Custom Fabrication and Design Solutions for Global Industries

DECCOFab delivers tailored design and fabrication systems, integrating Lean construction principles to maximize efficiency and minimize costs. From conceptual modeling to Factory Acceptance Testing, our team creates custom solutions that meet the most demanding project schedules.

At DECCOFab, we specialize in delivering custom-designed systems that support clients worldwide. Our approach combines advanced technology, skilled craftsmanship, and Lean construction principles to maximize prefabrication and efficiency. With expertise in producing pipe spools, utility panels, and custom skids, our team works closely with project partners to develop innovative, cost-effective solutions that meet even the tightest deadlines.

Fabrication Facility

Our state-of-the-art 25,000-square-foot facility is equipped to handle a wide range of fabrication projects. With dedicated areas for utility and process piping systems, five overhead cranes, and separate high-bay areas for stainless steel fabrication, we maintain a controlled environment to ensure precision and quality. Our facility also includes ASME-certified welding rooms and assembly spaces for pipe spools and custom assemblies.

By prefabricating components in our facility, we reduce on-site trade hours, lower costs, and increase safety during installation. Our ASME-certified pressure vessel fabrication, passivation, and electropolishing services guarantee compliance with FDA and BPE standards. Additionally, dedicated material receiving, inspection, and component kitting areas are organized under cGMP standards, ensuring accuracy and quality control at every stage.

3D Scanning and Virtual Design

Using 3D laser scanning, DECCOFab captures geospatial data to create highly accurate models, allowing clients to visualize their custom fabrications in their own environments. This advanced technology enhances design precision, reduces potential clashes between building systems, and streamlines the development process from concept to delivery. By incorporating constructability reviews and as-built assessments, our 3D scanning solutions reduce fieldwork and minimize safety risks.

Ultra-High Purity Teams

As one of the pioneers in ultra-high purity process contracting, DECCOFab serves industries with the most stringent cleanliness and purity standards. From microelectronics fabrication to gas distribution systems, our team is experienced in delivering solutions like coaxial tubing, specialty plastic piping, bulk gas distribution, and process tool installation. Our specialized capabilities ensure we meet the high-performance requirements of cutting-edge facilities.

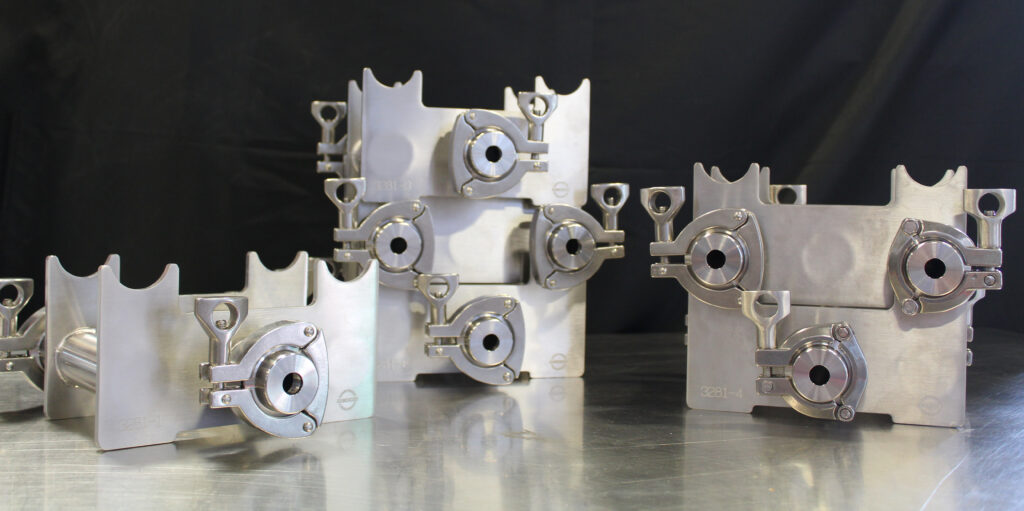

Custom Fabrication

We take pride in offering custom stainless steel and carbon steel fabrication services tailored to each client’s unique specifications. From custom carts and bag holders to pump stands, heat exchanger stands, and staircases, our team can fabricate a wide variety of structures to meet the specific needs of your project.

With a commitment to quality, precision, and safety, DECCOFab delivers exceptional custom solutions, no matter the complexity of your project. Let us help bring your vision to life through innovative design, advanced fabrication, and industry-leading expertise.