Advanced High Purity Cleaning, Passivation, and Polishing for Critical Applications

Clean for Oxygen (O2) Service

Originally designed as a cleaning specification for oxygen-rich environments, Clean for Oxygen Service ensures the removal of microscopic impurities and contaminants that could compromise product quality, safety, or performance. Due to the precision and rigor required, this process achieves an exceptional level of cleanliness that is not only highly desirable—but often essential—for today’s high-purity systems. It is now a standard requirement in industries such as pharmaceuticals, semiconductors, biotechnology, food & beverage, aerospace, medical devices, and industrial gases, where even the smallest contamination can have critical consequences.

Within our ISO 8 certified cleanroom, we adhere to the high-purity cleanliness standards, including American Society for Testing and Materials (ASTM) G93 Level A and Compressed Gas Association (CGA) G4.1.

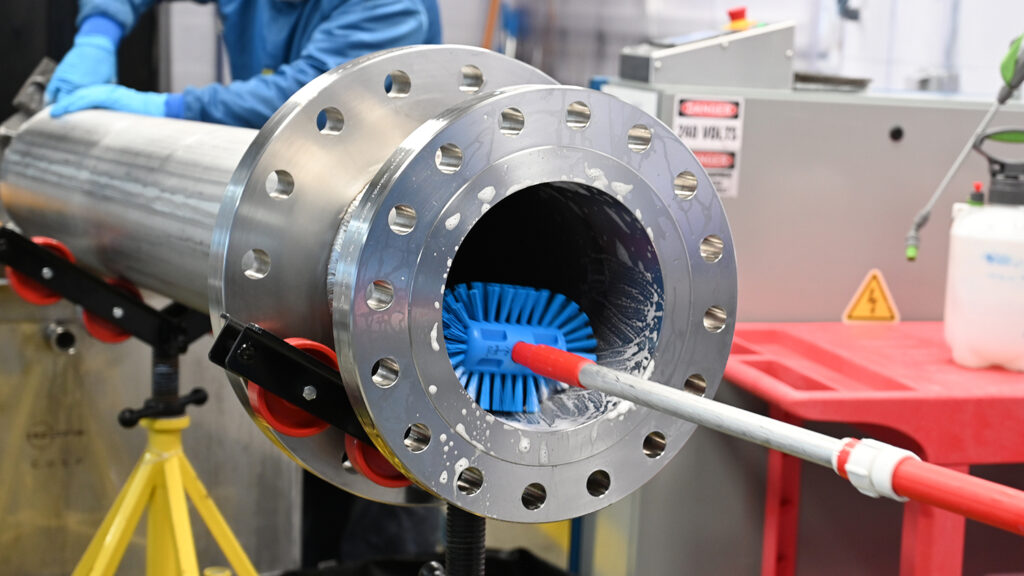

We perform our Cleaning for Oxygen Service at our High Purity Processing Facility. Our Critical Equipment Handling team collaborates closely to carefully remove, transport, and ship sensitive equipment to and from our facility. After servicing, our skilled technicians can reinstall the equipment to ensure a seamless process.

We can handle all ranges of your Cleaning for Oxygen Service needs — from the smallest components and fittings to 10-gauge, 18-inch diameter, 20-foot lengths of pipe, and vessels up to 8 feet in diameter and 10 feet long. These services comply with industry standards to ensure the highest level of safety and performance.

- Comprehensive High-Purity Cleaning – Removal of organic and inorganic contaminants, including oils, greases, and particulates to meet ASTM G93 Level A and CGA g4.1 standards.

- Certification – Clean for O2 Service certification provided upon completion.

- Packaging – Items are sealed and packaged to maintain cleanliness until installation. Double bagging and nitrogen overlay bagging are available upon request.

- Documentation – cGMP documentation is provided with each project.

Passivation Services

Passivation is a process that enhances the corrosion resistance of stainless steels and higher alloys by removing free iron and other surface contaminants, allowing a protective oxide layer to form on the cleaned surface. DECCO offers full in-house and field passivation services to improve the longevity and reliability of equipment used in critical environments.

Our 20,000 sq ft facility allows us to handle the largest projects, and volumes in-house. With easy access to the highway and a large logistics yard outside of our facility we make it easy for drop off and pick up of any equipment size. This location is also our base of operations for our in-field passivation services. With our vast assortment of equipment we are able to accommodate a multitude of client field requests.

Service Highlights:

- Surface Treatment: Utilization of proprietary cleaning chemistries to create a thick passive layer on stainless steel surfaces.

- Compliance: Adherence to ASTM A967 and ASTM A380 standards.

- Documentation: cGMP compliant Passivation Report Packages.

- We are able to adapt our testing methods to meet our clients needs.

- Customization: Tailored chemistries and procedures to meet specific client requirements and industry standards.

These services are essential for maintaining the integrity and performance of equipment in industries such as biopharmaceuticals, energy, aerospace, and chemical.

Full Mechanical Polishing & Electropolishing

We offer full mechanical polishing and electropolishing services for all process contact surfaces, vessel exteriors and skids, stainless mezzanines, stairs, and more. Our services are available both in-house and in the field, providing comprehensive solutions for all your mechanical polishing and electropolishing needs.